How Strategic Facility Maintenance Aids in Cost Savings

May 17, 2024

Medical Office Cleaning: Key Areas to Prioritize

July 11, 2024Businesses across industries face a common challenge — keeping their operations running smoothly and efficiently. From production lines to classrooms and hospital wards, the key to maintaining seamless productivity lies in a robust equipment maintenance strategy. Failing to prioritize this critical aspect can have far-reaching consequences, from compromised safety to costly downtime and premature equipment failure.

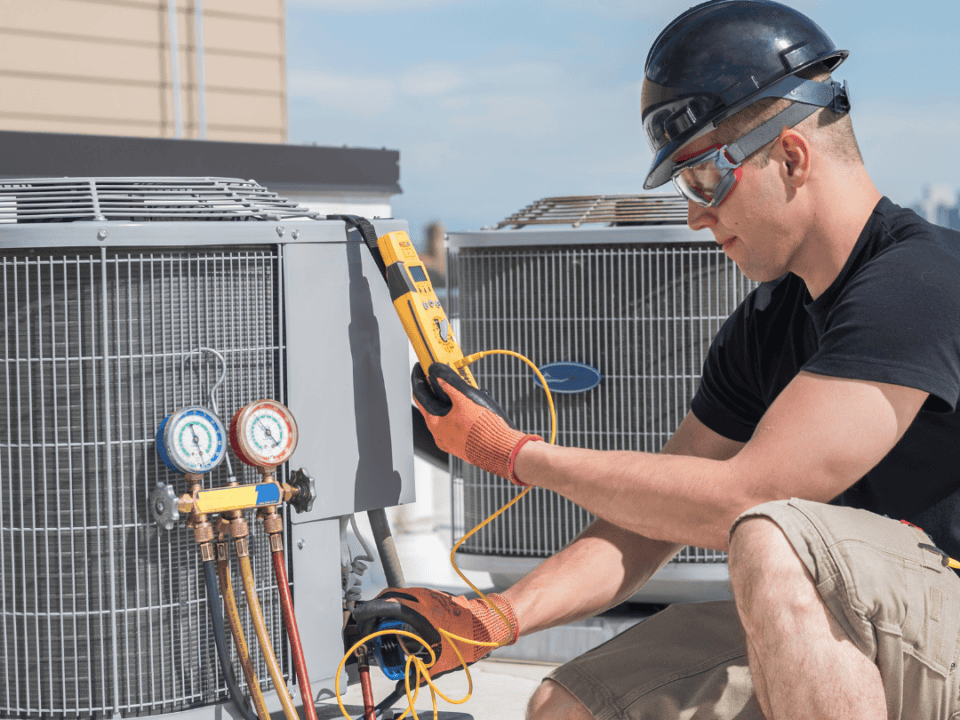

Equipment Maintenance — What, Why, How

Equipment maintenance encompasses any procedure performed on a business’s equipment — from tools and machinery to HVAC systems and computer systems — to ensure its reliable and optimal operation. It involves both routine scheduled maintenance, as well as corrective repairs.

The advantages of proper equipment maintenance are manifold for businesses across industries. Primarily, equipment maintenance minimizes equipment downtime by keeping all components operating, quite literally, like a well-oiled machine. This, in turn, enhances safety, boosts productivity and efficiency, and increases output capacity. These then lead to significant cost savings by preventing costly repairs and prolonging the lifespan of equipment, ultimately contributing to higher revenue generation.

Typically, equipment maintenance involves routine inspections conducted at intervals based on usage hours. Nowadays, with AI and monitoring capabilities integrated into nearly every system, it’s easy to track the daily usage hours of each piece of equipment and receive alerts when maintenance inspections are due.

Cross-Industry Equipment Maintenance

Any industry that uses any kind of equipment uses equipment maintenance. Notable examples include:

Equipment Maintenance in Manufacturing

As previously mentioned, one of the most significant benefits of equipment maintenance is minimizing downtime, which is particularly crucial in manufacturing settings. According to Forbes, unplanned downtime can cost industrial manufacturers up to $50 billion annually, with equipment failure being the root cause of nearly 50% of all downtime incidents. In the automotive industry alone, a single minute of downtime can cost an average of $22,000!

Furthermore, any downtime across the supply chain or factory floor inevitably leads to decreased output. In today’s highly competitive and consumer-driven market, eager customers simply won’t wait for production delays. Consequently, not only do manufacturers risk incurring costly repairs, but they also risk losing valuable clients.

Within this context, it becomes evident that ongoing factory maintenance is an absolute necessity. Adhering to a factory scheduled maintenance plan can alleviate stress by ensuring consistent checkups and upkeep of essential equipment, including:

- Assembly lines

- Industrial machinery

- Conveyor belts

- Robotics and automated systems

- Packaging equipment

- Material handling equipment (forklifts, cranes, etc.)

- Hydraulic and pneumatic systems

- Electrical and control systems

By proactively maintaining these critical manufacturing assets, companies can minimize the risk of unplanned downtime, increase operational efficiency, and ultimately protect their bottom line.

Equipment Maintenance in Schools

Unlike manufacturing, where equipment maintenance focuses on maximizing output, schools’ equipment maintenance prioritizes areas that directly impact students’ health, safety, and educational experience.

For instance, HVAC maintenance is a top priority of school maintenace, as these systems maintain indoor air quality and temperature, essential for creating a comfortable learning atmosphere. Regular maintenance of toilet facilities is also critical to ensure hygiene and prevent the spread of illness. Additionally, maintaining computer and science lab equipment is vital to support effective teaching and learning.

In addition, schools must comply with stringent health and safety regulations, making regular inspections and equipment maintenance non-negotiable. This compliance ensures that any potential hazards are addressed promptly, minimizing risks to students and staff.

Safeguarding students’ well-being, from health to fostering optimal learning environments, lays the foundation for increased academic success. This comprehensive approach ensures that students can focus on their studies without concerns about their safety or comfort, leading to better concentration, higher engagement, and, ultimately, improved academic outcomes.

Equipment Maintenance in Hospitals

In healthcare settings, equipment maintenance extends beyond operational efficiency — it is a matter of life and death. Hospitals rely on a vast array of sensitive, life-saving equipment that must function optimally around the clock, leaving no allowance for maintenance mishaps or equipment failures.

Unlike other facilities, hospitals face a uniquely challenging task when it comes to equipment maintenance. Diagnostic machines like MRI and CT scanners, surgical tools, patient monitoring devices, and ventilators are just a few examples of critical medical equipment that require meticulous maintenance to ensure accurate and reliable performance at all times.

Not only does proper maintenance safeguards patient health and safety, but it also increases the lifetime value of these expensive medical devices. Regular upkeep can extend the lifespan of equipment, saving healthcare facilities substantial costs in the long run. It also ensures equipment availability when needed, reducing downtime and improving operational efficiency.

Hospitals should follow a rigorous scheduled preventive maintenance plan, as waiting for equipment to break down is not an option. Regular inspections and maintenance routines help maintain equipment health, ensuring it supports the vital duty of keeping patients healthy. By maximizing the lifetime value of medical equipment through comprehensive hospital maintenance, healthcare facilities can better manage resources and improve the quality of care provided to patients.

Comprehensive Equipment Maintenance Solutions from US&S

Regardless of the industry or sector, ongoing equipment maintenance is an integral and indispensable component of any business’s operations. While each type of organization may have unique priorities and requirements, the common thread that binds them all is the understanding that proper equipment maintenance is the cornerstone of sustained, uninterrupted operations.

Given the paramount importance of equipment maintenance, adhering to a scheduled, comprehensive maintenance program is not easy, especially for teams struggling with time constraints and competing responsibilities in their day-to-day work.

This is where a reliable facility maintenance provider becomes valuable. As a leading provider of Operations and Maintenance (O&M) services, US&S offers comprehensive equipment maintenance solutions tailored to the unique needs of various industries, including manufacturing, education, and healthcare. With years of experience and a team of skilled technicians, US&S is well-equipped to support businesses in maintaining their critical assets and ensuring optimal performance. Contact us to request a consultation on how you too can take your equipment maintenance to the next level.